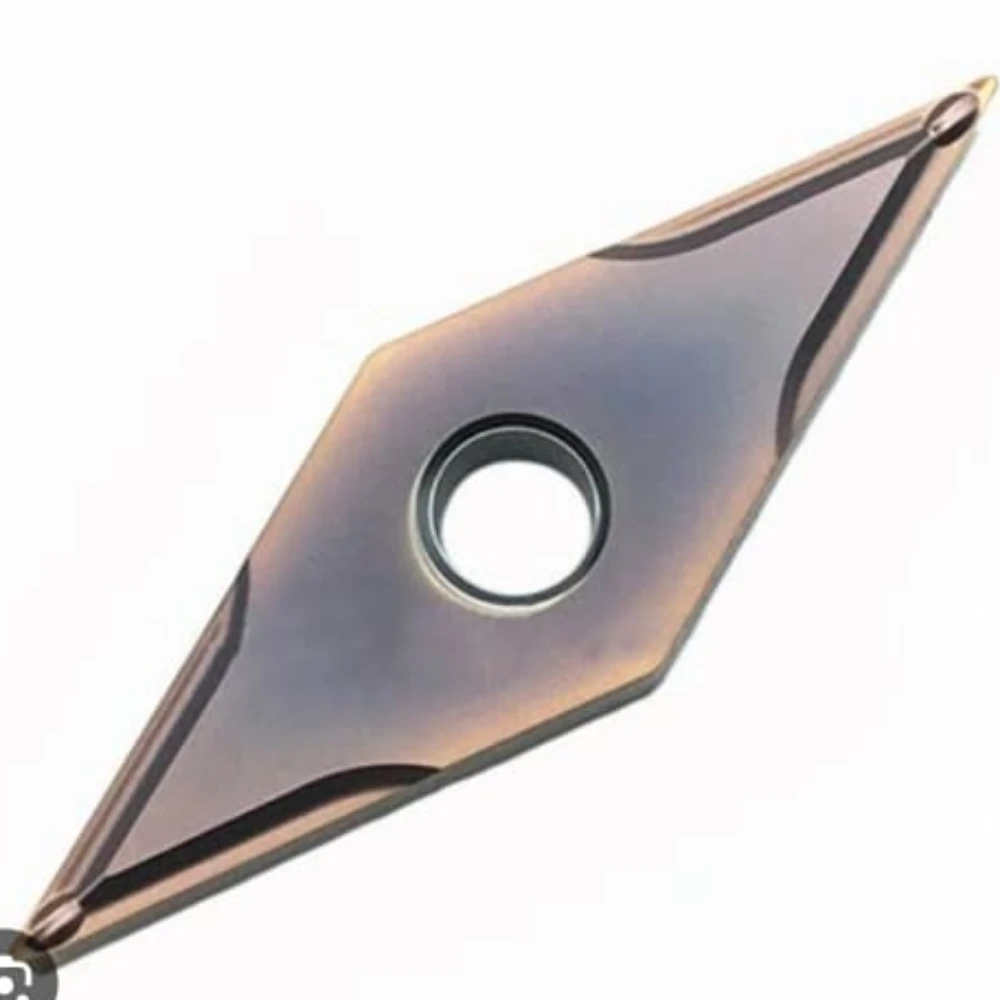

CCMT09T304-OTM OP1215 OKE

🔧 Insert Specifications

-

Insert Shape: Positive 80° rhombic (diamond-shaped)

-

Inscribed Circle (IC): 9.52 mm

-

Thickness (S): 3.97 mm

-

Corner Radius (RE): 0.4 mm

-

Cutting Edge Length (L): 4.4 mm

-

Grade: OP1215

-

Coating: PVD (Physical Vapor Deposition)

-

Substrate: High Co content with fine WC grain

-

Hardness: Approximately 1560 HV

-

Application: Semi-finishing to finishing operations on steel and stainless steel

-

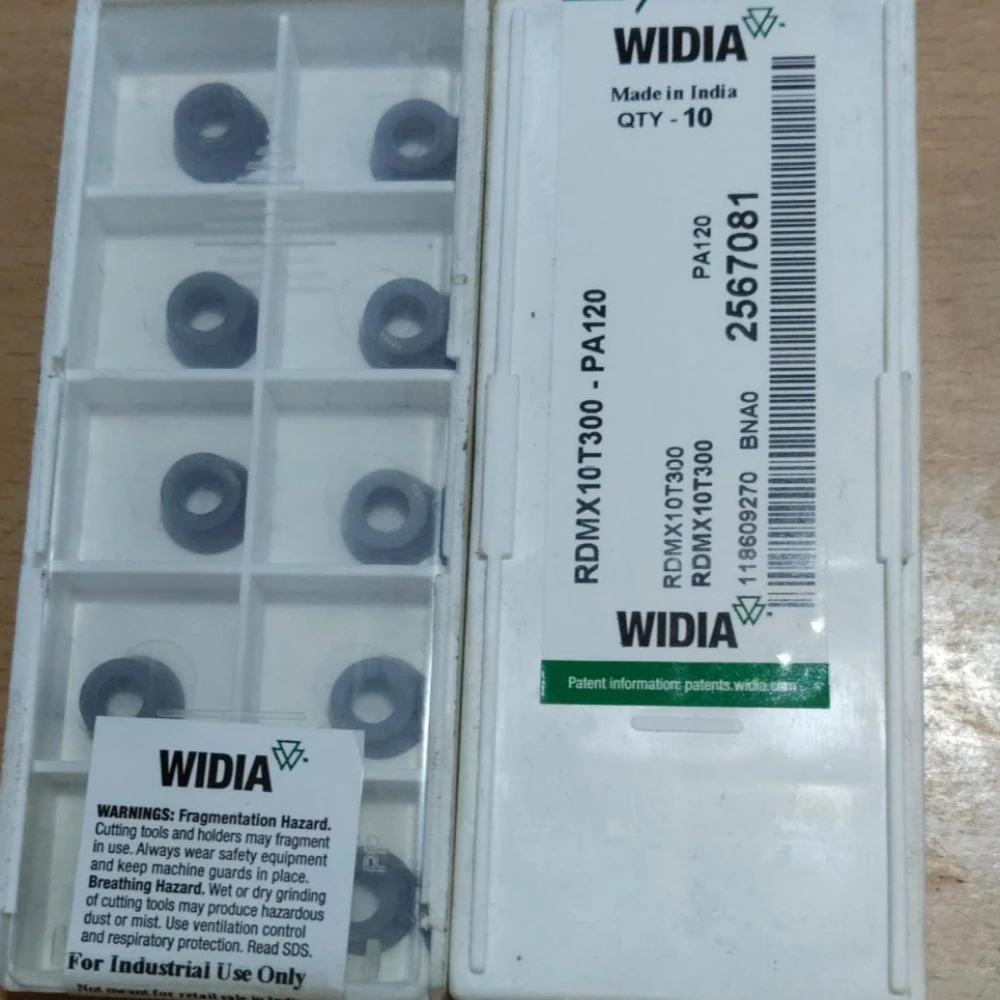

Packaging: Typically sold in packs of 10 inserts

⚙️ Performance Features

-

OP1215 Grade: Optimized for high-speed machining of steel and stainless steel, offering excellent wear resistance and surface finish.

-

PVD Coating: Provides enhanced hardness and thermal stability, suitable for continuous cutting operations.

-

Substrate Composition: High cobalt content and fine tungsten carbide grain structure contribute to improved cutting edge strength and durability.